RTLS Tool &

Equipment Tracking

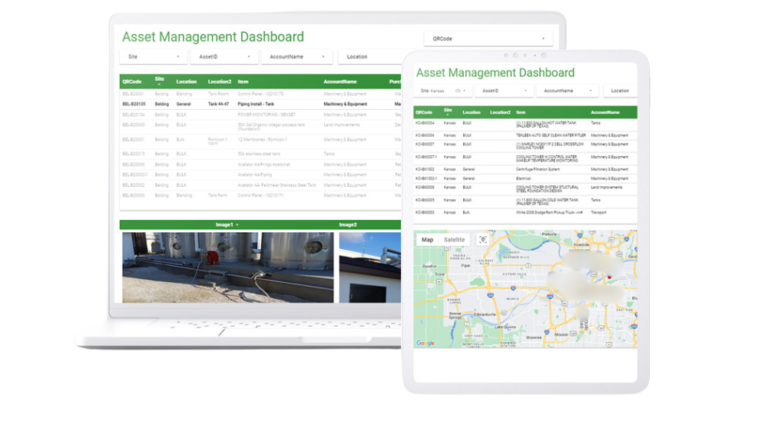

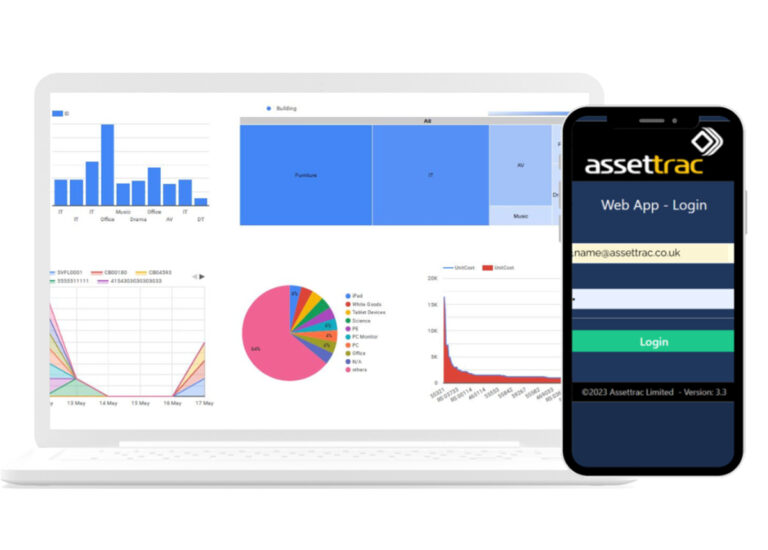

Teltonika Eye Beacon with Assettrac RTLS asset tracking software

Prevent Project Delays - Save Time - Reduce Equipment Costs

Delayed projects due to missing or misplaced tools and equipment cost your business money. Worse, many tools spend 70% of their time unused.

Whether on-site, in-transit or in a warehouse, manual asset management processes lead to a lack of real-time visibility for project managers and operations teams, disrupting workflows and increasing costs.

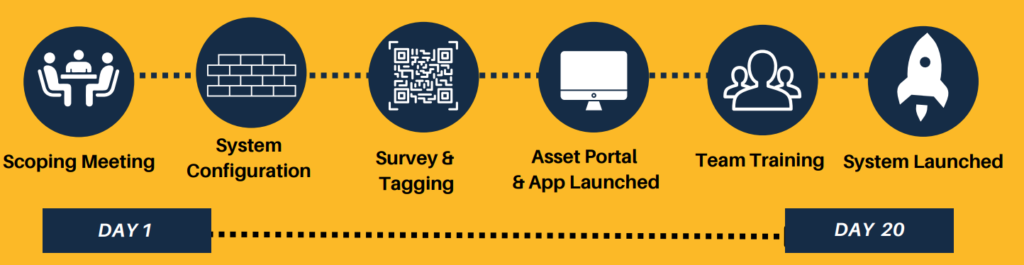

Real-time location tracking (RTLS) combined with Assettrac’s powerful, customised asset management software solves these problems.

Key Equipment Tracking Challenges for Construction,

Utilities & Facilities Companies

- How do I reduce theft and loss of equipment?

- How do I track equipment on-site, in a warehouse, being serviced or in-transit between locations?

- How can I quickly and easily find and allocate the right equipment to the right project?

- How do I reduce downtime on-site caused by missing equipment or delays?

- How can I optimise equipment allocation and usage to maximise ROI and reduce the risk and cost of duplicate purchases?

- Our manual process is taking too long, reliant on people at the item and the location is often out-of-date by the time it’s reported.

30%

Missing or misplaced tools and equipment, can account for up to 30% of your inventory, leading to delayed projects, under-utilisation of assets and operational inefficiencies.

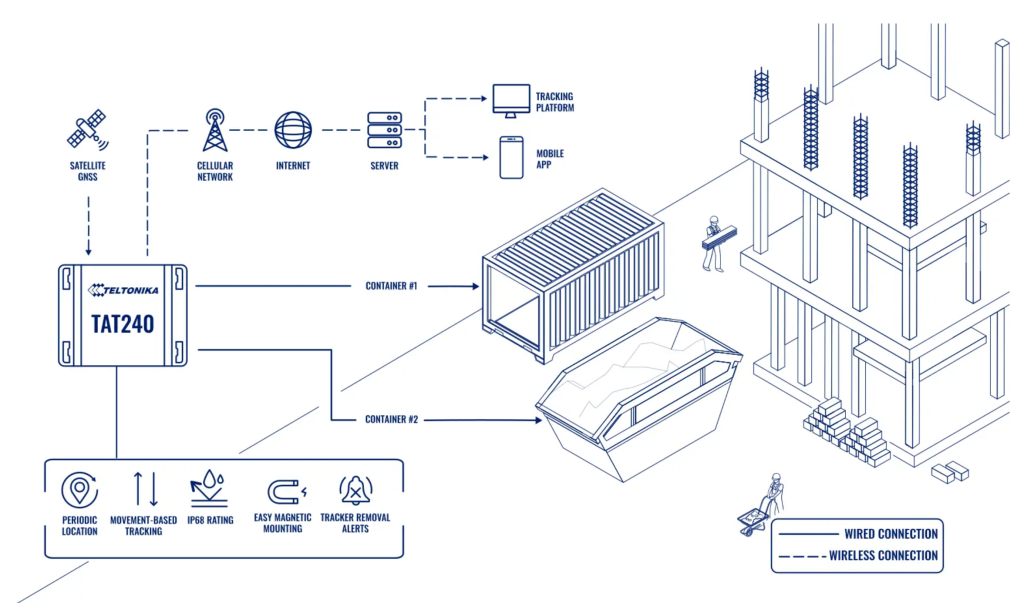

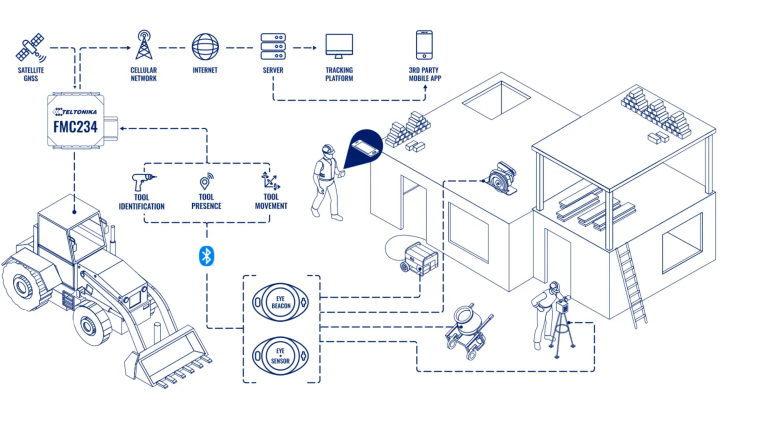

The RTLS Solution for Equipment Tracking: Eye Beacons & Sensors

Teltonika EYE Beacons and EYE Sensors are an effective solution for tracking tools and equipment on-site and in-transit with data seamlessly transmitted to Assettrac’s central asset management platform providing real-time visibility of tools and equipment in all locations.

EYE devices are compact, transmitting Bluetooth® signals to nearby gateways, such as Teltonika GPS trackers installed in on-site machinery or by workers’ smartphones or handheld devices. This automated system means that your team no longer needs to manually check and update records, saving huge amounts of time.

- Robust casing - built to withstand harsh environments with IP67-rated protection against dust and water.

- Long battery life

- Easy-to-mount and requiring no maintenance once installed.

- Group configuration - set up 1,000 EYE Beacons or Sensors as one.

- Scalable: Each GPS tracker scans up to 100 EYE devices simultaneously

- Continual scanning provides complete coverage.

- Movement timer - tracks the time a tool is actively moving, pausing when it stops and resuming as it moves again providing accurate user data for scheduled maintenance based on usage.

- Seamless integration & easy to implement with existing Teltonika trackers and smart devices

EYE Devices In Action: Construction Company

A Swiss construction company faced a constant struggle with the costs and inefficiencies caused by missing tools, project delays, high rental costs, and countless wasted work hours trying to solve the problem. The company was losing up to 100 hours per week as depot, fleet, and site managers struggled with manual equipment tracking, while construction workers were filling Excel sheets and sharing tool locations via messaging apps.

Teltonika EYE Beacons helped them achieve full automated precise location tracking and reporting. As a result, missing assets became a thing of the past.

The results had a significant impact on the business’ results, saving around 114,000 Swiss francs ( 120,000 euros) per year on equipment purchases and rentals. In addition the operation is more efficient. asteams can focus on project delivery rather than chasing missing equipment.